At ![]() , our range of Synthetic Polymer (EVA) and Polyolefin based products are developed for a wide diversity of applications which includes pleating with separators, edge sealing and the bonding of complex materials from Polyolefin fibres to Polytetrafluoroethylene (PTFE). Our R&D laboratory team is constantly formulating and testing adhesive’s performance to meet the increasing demand in the air filtration industry. The product overview below represents a selection from our extensive range. We will be pleased to offer a comprehensive range of custom-made solutions upon request.

, our range of Synthetic Polymer (EVA) and Polyolefin based products are developed for a wide diversity of applications which includes pleating with separators, edge sealing and the bonding of complex materials from Polyolefin fibres to Polytetrafluoroethylene (PTFE). Our R&D laboratory team is constantly formulating and testing adhesive’s performance to meet the increasing demand in the air filtration industry. The product overview below represents a selection from our extensive range. We will be pleased to offer a comprehensive range of custom-made solutions upon request.

Air Filter

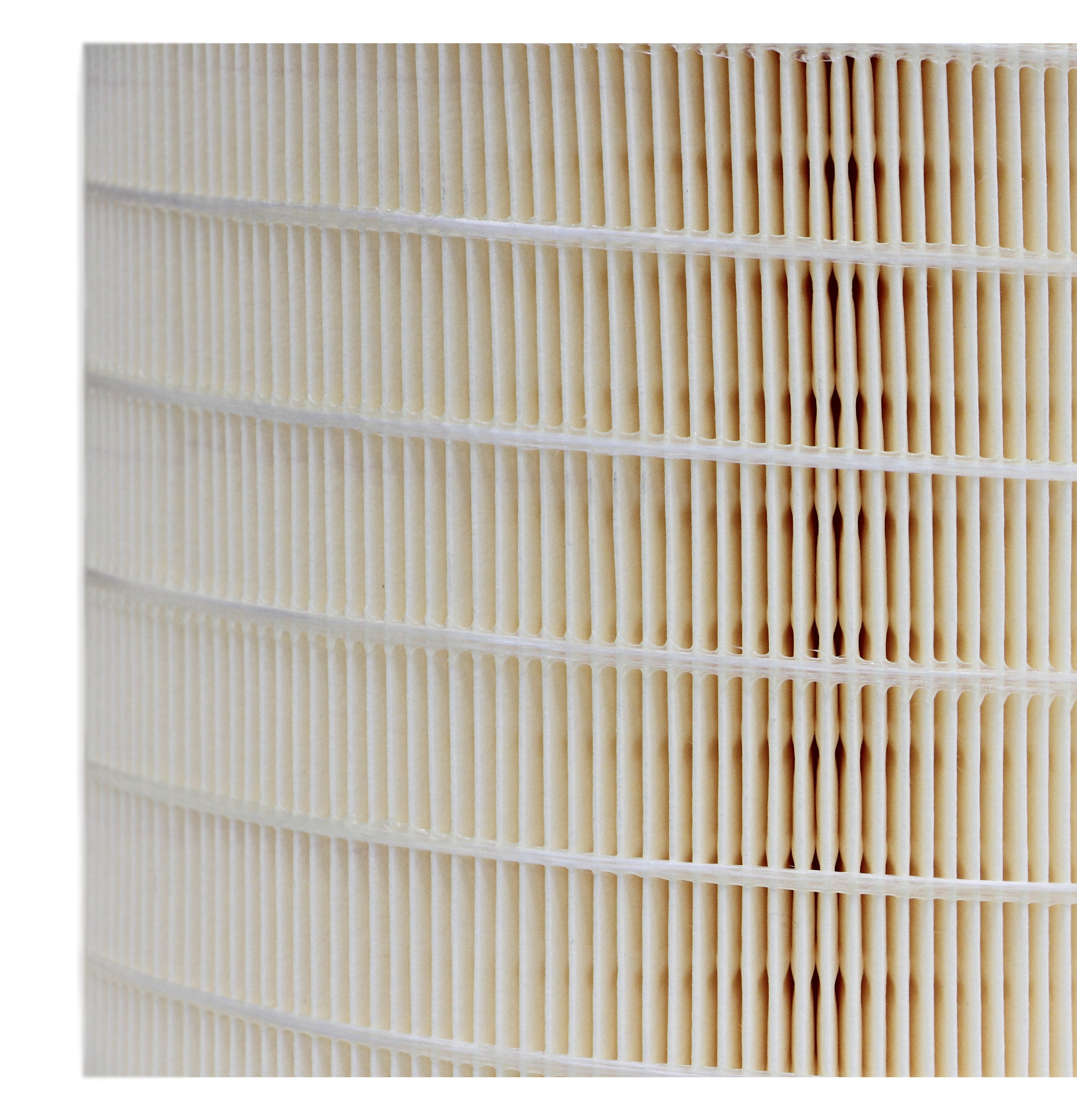

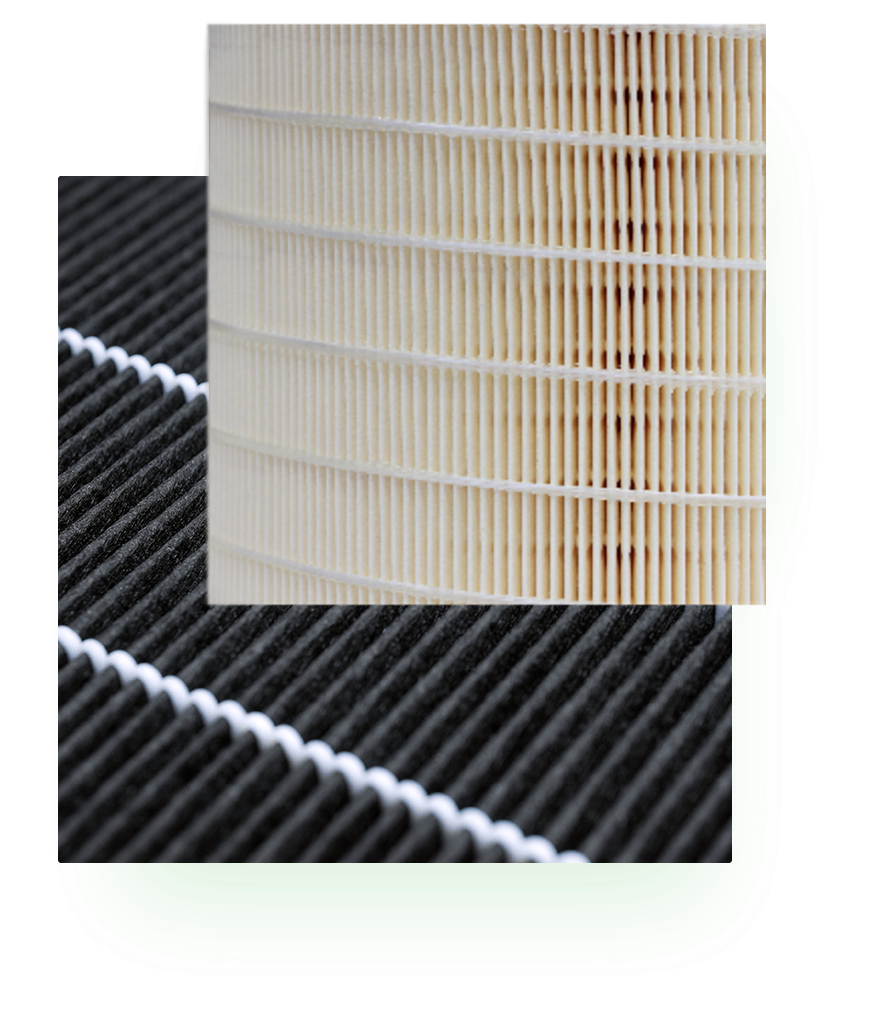

Pleating

The hotmelt separators maintain its uniform spacing between pleats to allow optimal flow of air into and through the filter. Polyolefin based & Synthetic Polymer (EVA) have a wide product portfolio with range of viscosities and curing time to suit desired continuous or inter-mitten glue line pattern and machine line speed. Our hotmelt adhesives are designed with high initial tack and have longer working window to make a perfect pleat to suit our customer different requirements, production processes and geographical standards.

Apart from the conventional requirements, we do have products to suit customers using foaming technology. Adhesive foaming technology with a balance mixture of inert gas with hotmelt adhesives will help to reduce adhesive consumption and improved overall bonding performance.

| Product | Code | Characteristics | |

|---|---|---|---|

| Synthetic Polymer (EVA) | 336J |

|

Request TDS |

| Synthetic Polymer (EVA) | 337N |

|

Request TDS |

| Synthetic Polymer (EVA) | 336C |

|

Request TDS |

Edge Sealing

In the challenging sector for home appliances air filter, Aica Melt hotmelt adhesive provide an alternative to the polyurethane based hotmelt for casting circular filters used in the vacuum cleaner. It also provides solution for other air filter cartridge that require additional bonding reinforcement to enhance its durability properties after exposure to external forces.

| Product | Code | Characteristics | |

|---|---|---|---|

| Synthetic Polymer (EVA) | 315P |

|

Request TDS |

| Polyolefin | 912M |

|

Request TDS |

| Polyolefin | 913M |

|

Request TDS |

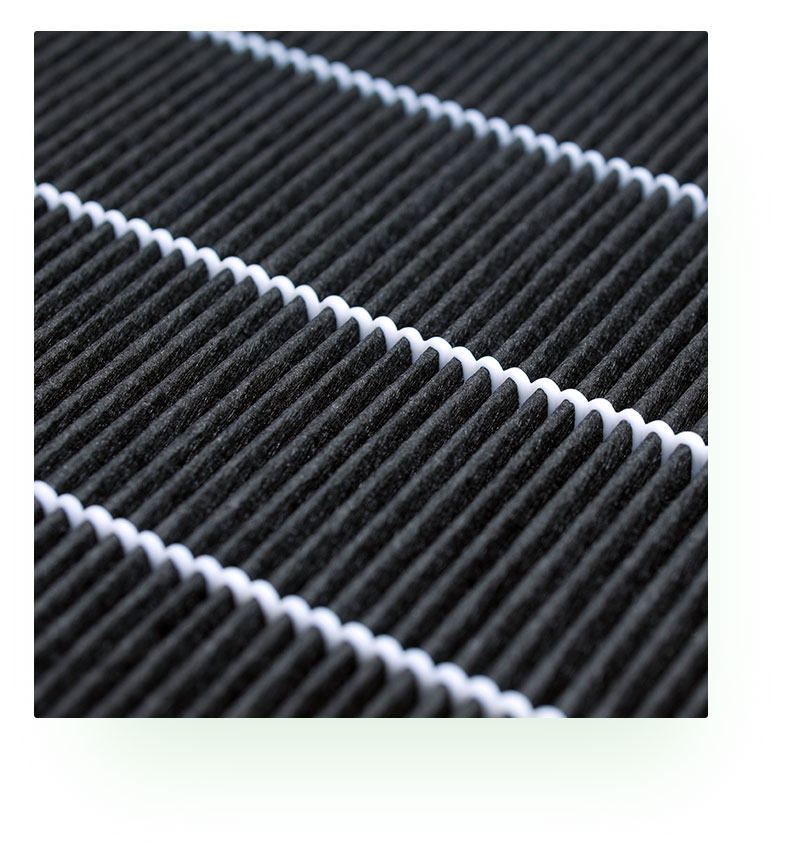

Cabin Filter

Aica Melt products have high creep resistance are suitable for the automotive industry particularly in sealing the cabin air filters.

| Product | Code | Characteristics | |

|---|---|---|---|

| Synthetic Polymer (EVA) | 380C |

|

Request TDS |

At ![]() , our range of Advin-ECO and Advin-Prime products are developed for a wide diversity of applications which includes pleating with separators, edge sealing and the bonding of complex materials from Polyolefin fibres to Polytetrafluoroethylene (PTFE). Our R&D laboratory team is constantly formulating and testing adhesive’s performance to meet the increasing demand in the air filtration industry. The product overview below represents a selection from our extensive range. We will be pleased to offer a comprehensive range of custom-made solutions upon request.

, our range of Advin-ECO and Advin-Prime products are developed for a wide diversity of applications which includes pleating with separators, edge sealing and the bonding of complex materials from Polyolefin fibres to Polytetrafluoroethylene (PTFE). Our R&D laboratory team is constantly formulating and testing adhesive’s performance to meet the increasing demand in the air filtration industry. The product overview below represents a selection from our extensive range. We will be pleased to offer a comprehensive range of custom-made solutions upon request.

Pleating

The hotmelt separators maintain its uniform spacing between pleats to allow optimal flow of air into and through the filter. Polyolefin based & Synthetic Polymer (EVA) have a wide product portfolio with range of viscosities and curing time to suit desired continuous or inter-mitten glue line pattern and machine line speed. Our hotmelt adhesives are designed with high initial tack and have longer working window to make a perfect pleat to suit our customer different requirements, production processes and geographical standards.

Apart from the conventional requirements, we do have products to suit customers using foaming technology. Adhesive foaming technology with a balance mixture of inert gas with hotmelt adhesives will help to reduce adhesive consumption and improved overall bonding performance.

Product

Code

336J

Characteristics

- White glue pellet

- Fast setting

- Long open time

- Good heat stability

- Good bonding to filter paper

Product

Code

337N

Characteristics

- White glue pellet

- Low shrinkage

- Fast setting

- Long open time

- Excellent bonding to filter paper

Product

Code

336C

Characteristics

- White glue pellet

- High viscosity

- Fast setting

- Long open time

- Suitable for hot melt foaming technology

- Excellent bonding to filter paper

Edge Sealing

In the challenging sector for home appliances air filter, Aica Melt hotmelt adhesive provide an alternative to the polyurethane based hotmelt for casting circular filters used in the vacuum cleaner. It also provides solution for other air filter cartridge that require additional bonding reinforcement to enhance its durability properties after exposure to external forces.

Product

Code

315P

Characteristics

- Translucent white glue pellet

- High viscosity

- Slow setting

- Long open time

- Used on the paper, cloth and plastic related application

Product

Code

912M

Characteristics

- Off-white glue block

- Moderately setting

- Low viscosity

- Good heat resistance

- Good open time

- Very good sealing property

Product

Code

913M

Characteristics

- Off-white glue block

- Moderately setting

- Good heat resistance

- Good open time

- Very good sealing property

Cabin Filter

Aica Melt products have high creep resistance are suitable for the automotive industry particularly in sealing the cabin air filters.

Product

Code

380C

Characteristics

- White glue pellet

- Moderate open time

- Good bonding between styrofoam, PU foam, paper, wooden particle board and non-woven fabric